Cookies are used on this site. We can use them to evaluate site usage in order to display usage-based content and advertising. By using the site, you consent to the use of cookies. More info

A major milestone has been achieved: Fox Sunny Citrus from Coop is the first product in a bottle made from our own recycled material

The first bottle made from Steinfels Swiss recycled material has been available in stores since July 2023.

The bottle containing the Fox brand Sunny Citrus washing-up liquid was developed and launched together with Coop. With each bottle the equivalent weight in virgin HDPE (40 g) is saved, corresponding to savings of 16 tonnes a year.

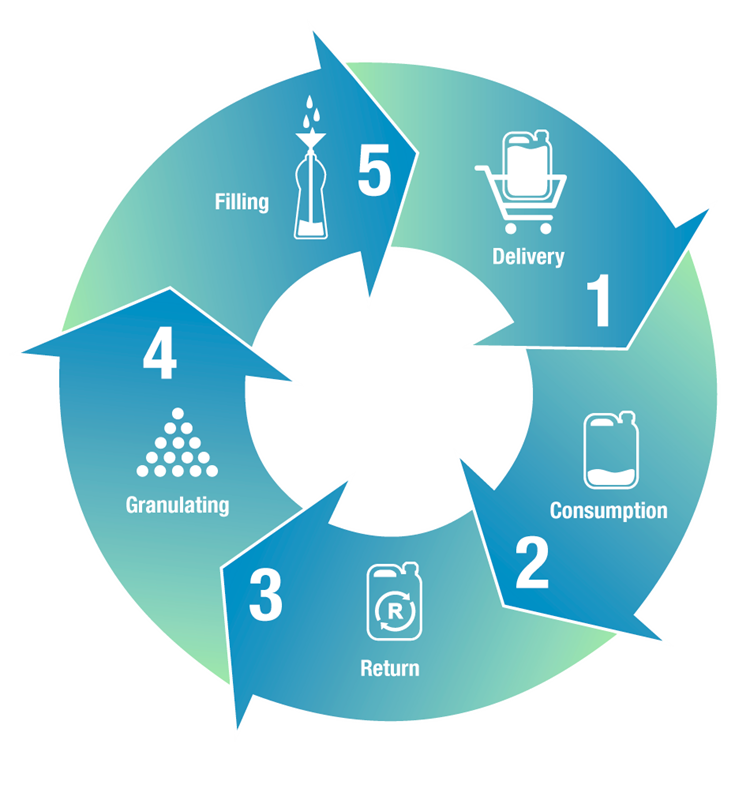

Delivery (1)

Steinfels Swiss supplies commercial customers such as restaurants, hotels, care homes and hospitals with detergents and cleaning products in plastic containers. The colourless containers are made of high-quality, single-origin HDPE (virgin HDPE), which is returned to the recycling loop for reprocessing after use.

Use and returns (2 and 3)

Once the detergents and cleaning products have been used up, Steinfels Swiss collects the empty containers from its customers. These are delivered to our certified recycling partner for the recycling process.

Regranulation and cleaning (4)

Our recycling partner ensures that the containers are completely empty before shredding them and cleaning them thoroughly to eliminate any product traces and odours. The cleaned HDPE is then granulated.

Production and filling (5)

The recycled, processed HDPE granulate is then used to manufacture new containers.

100% of the recycling process takes place in Switzerland

Steinfels Swiss has collected empty containers from its customers for many years. Already today, they enter the recycling process where they are turned into granulate and used in applications with low quality requirements. In the past two years, in cooperation with certified Swiss partners with many years of experience in recycling and the manufacturing of packaging, a closed recycling loop for high-quality granulate was developed.

Processing was optimized to achieve an odourless, colourless granulate. This granulate is made into new bottles that Steinfels Swiss can again fill with detergents.

Collaboration with Swiss partners

Recoplast, a company that processes plastics for reuse, and the Semadeni Plastics Group with its group company Biplast contributed their technical expertise to develop the process with Steinfels Swiss. Semadeni has been producing plastic items for various applications for 65 years, using recycled material whenever possible.

“When it came to choosing partners for container recycling and bottle manufacturing, I only considered environmentally certified Swiss companies,” says Christian Koch, CEO of the Steinfels Swiss Division. “The combined knowledge and know-how allowed us to realize the vision of our own recycling loop.”

Reducing emissions through recycling

“The manufacturing and conventional disposal of virgin HDPE produces almost five times more emissions than the use of recycled material,” explains Patrick Semadeni, CEO of the Semadeni Plastics Group and vice-president of Kunststoff.swiss, the umbrella organization for the plastics industry in Switzerland, where he is in charge of sustainability.